|

|

HJEM JERNBANER • Sporvogne & Busser • Tog i remisen • Gæstebilleder • Udenlandske tog • Lokschuppen • Tog i Tyskland • 74 | 81 | 87 • EMD/GM Maskiner • Rayton's US Trains DSB CLASSIC • DanLink • Driftsmateriel • Jernbanemuseet • GM Togmaskiner • Lyntog Litra MA • S-tog & Bybane • Jernbanefærger • Stationer EN SLAGS NYHEDER • 2027 | 2026 | 2025 • 2024 | 2023 | 2022 • 2021 | 2020 | 2019 • 2018 | 2017 | 2016 • 2015 | 2014 | 2013 • 1980-89 | 1990-12 BIBLIOTEK • Havet og Omegn • Interview & artikler • Runabåden "Snarken" • COP15 & the Movies" • biografmuseet.dk • in70mm.com • youtube.com |

|

Extracts

and longer parts of hauerslev.com may only be reprinted with the

written permission from the

editor. |

The EMD Success Story

|

Tilbage

til forsiden |

| Skrevet og fotograferet af: GM EMD, 1988. Forberedt for hauerslev.com af Anders M Olsson, Lund, Sverige | Dato: 15.07.2014 |

The

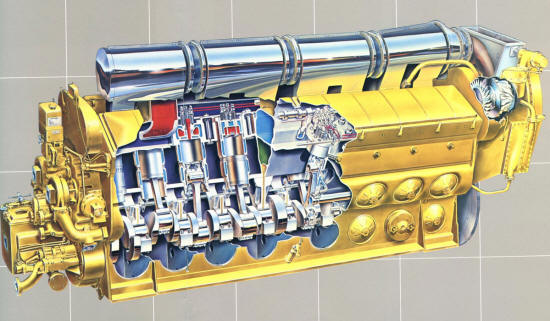

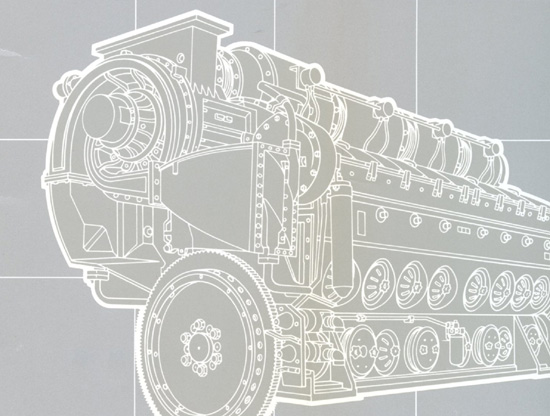

EMD 645 engine introduced in 1965. Click the image to see an enlargement The

EMD 645 engine introduced in 1965. Click the image to see an enlargement120 million horsepower! That's how much power Electro-Motive Division of General Motors has produced. Electro-Motive Division (EMD) of General Motors is the only medium-speed Diesel engine manufacturer in our size range to have put that much power to work. It all began with a decision that must be described as courageous. It was at the height of the Depression in the United States that General Motors management committed millions of hard-to-get dollars to the development of a lightweight, compact, two-stroke cycle Diesel power unit. The result was a revolutionary Diesel engine incorporating a patented unit injector fuel system and a basic engine design far superior to any offered in the world at that time. The first prototype GM Diesel engines were used in 1933 to provide power for the Chevrolet assembly line at the Chicago "Century of Progress". Development of these versatile, durable powerplants opened a new world of potential applications for Diesel power. The intervening years have seen that design overtake steam on United States and international railroads, while catapulting Electro-Motive Division of General Motors to a leadership position in the marine propulsion and offshore oil rig power markets. And we plan to remain the leader in the years ahead. It is a challenge we have been preparing more than 60 years for. |

Læs

mere her: GM / EMD Electro Motive Division's Diesellokomotiver Motive Power Dependability from Electro-Motive Baner og tog fra da mor var dreng Historien om DanLink - DSB 1986-2000 Internet link: |

Leadership |

|

1934 - The world's first Diesel-powered passenger revenue locomotive opens

the second year of the Century of Progress, ushering the Diesel-electric

into main line passenger service. 1934 - The world's first Diesel-powered passenger revenue locomotive opens

the second year of the Century of Progress, ushering the Diesel-electric

into main line passenger service.1938 - GM/EMD introduces the 567 series engine. 1939 - Electro-Motive builds the first Diesel-electric freight locomotive. Within 20 years Diesel was doing 100 percent of the work on America's railroads. The first propulsion unit and the first reverse reduction gear equipped Diesel-mechanical drive were delivered to the marine industry. 1942-45 - 3,000 GM/EMD Diesels provide dependable marine power in World War II service. 1946 - Delivery of first export locomotive to Mexico. 1950 - Delivery of the first engine for Associate Locomotive manufacture. 1954 - GM/EMD introduces a line of mobile Diesel-electric generating units. 1955 - First line of Diesel-electric oil drilling equipment introduced, designed to replace mechanical drives. 1959 - Turbocharged 567 engine introduced. 1965 - 645 Series engine introduced. 1975 - Delivery of 1,000th marine oil drilling unit. 1978 - 100 millionth horsepower milestone reached. 1980 - 6,000th marine diesel engine produced. 1983 - 50,000th locomotive completed. |

|

The Experience |

|

The majority of the 60,000 GM/EMD Diesel engines built since 1938 are still

in use. More than 80 percent of the locomotives in North America were built

by GM/EMD. Overseas, nearly 60 countries have chosen GM power to keep their

railroads running efficiently. The majority of the 60,000 GM/EMD Diesel engines built since 1938 are still

in use. More than 80 percent of the locomotives in North America were built

by GM/EMD. Overseas, nearly 60 countries have chosen GM power to keep their

railroads running efficiently.Of course, we do more than provide power for locomotives. The same constant dedication which made us the world's leading producer of locomotives has served us and our customers equally well in the marine and power products community. Today, that dedication has made us the number one maker of Diesel engines for workboats and the number one maker of Diesel engines for offshore drilling rigs. These are America's finest medium-speed Diesels. And we stand behind these products with a comprehensive service and parts network dedicated to offering service support anywhere your GM/EMD equipment may be in operation, supplying parts quickly and to specifications. No one offers the breadth and depth of service support that GM/EMD does. This is a record of achievement which bespeaks of a high standard of performance, simplicity and reliability. |

|

The Technology |

|

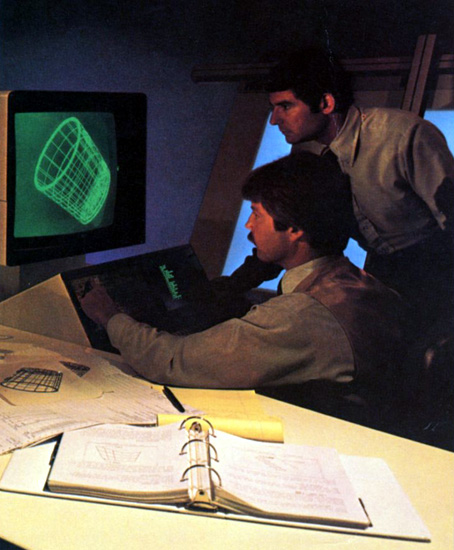

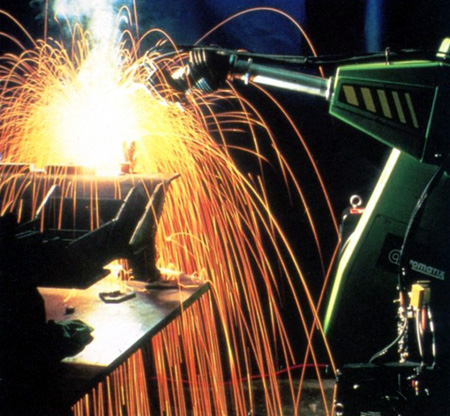

CAD/CAM CAD/CAMR&D. Research and Development. It's not a luxury for any company. We're committed to continually devoting a significant percentage of our investment capital to research, development and state-of-the-art machinery. If you were to tour our massive 4,000,000 square foot (372,000 square meters) plant, you'd be likely to run into some of the most advanced experiments and futuristic manufacturing technology in the world. After all, we didn't get to be the number one producer of medium-speed Diesels by sitting on our laurels. On the contrary, the technology of the future is in our operations today. CAD/CAM... is a valuable tool for us and our customers. Computer Aided Design eliminated the repetitive, time-consuming steps required to redesign equipment. Today, we are involved in the second phase of CAD/CAM, Computer Aided Manufacturing. With Computer Aided Manufacturing, designs stored in computers are being used to direct the manufacture of parts and assemblies. Robot Deburring Operations... In one of the first applications of its kind, robots are used to debur engine pieces of potentially damaging metal chips. The use of advanced robot technology in this process saves time, money, and produces a consistently higher quality product. Powdered Metals Technology... GM/EMD advanced this manufacturing process to a new plateau of achievement, with development of high-temperature sintering technology that allows us to make parts of superior strength, without a lot of costly extra machining. With one stroke of the press, parts are formed to their final size and shape. Robot Arc Welding... Using this latest technology in welding, EMD achieves a significant increase in productivity and quality. Use of this technology in large assemblies provides a more uniform, consistent, higher quality product at lower cost. Laser Hardening... To give the liners in our turbocharged Diesels longer life, we use the world's largest industrial laser - a controllable heat source for optimal metallurgical hardening. Laser hardening significantly reduces cylinder wear, offering operators of these engines a considerable savings on maintenance and overhaul. |

|

Robot Arc Welding Robot Arc WeldingComputerized Test Facilities... Our skilled engineers are supported by some of the most advanced engine test facilities in the industry. Highly sensitive test cell equipment simulates real world conditions, providing valuable data for the designs of today and tomorrow. Computer Controlled Machines... Self-feeding, self-sensing machines that adjust themselves for variations in temperature or condition of stock. GM/EMD was a forerunner in their application in industrial settings. The resulting production uniformity assures a precise, quality product. Stringent Quality Control... Dependability is built into every part and process through stringent statistical quality control methods. These methods signal the dramatic transformation taking place in forward-thinking manufacturing operations today. Components are thoroughly watched through computerized, statistical methods during the production process, not after like most traditiona1 manufacturers. In this way potential errors can be prevented before they are produced. These in-process checks mean a better product for you. These are but a few of the advanced engineering and manufacturing technologies of Electro-Motive Division of General Motors. Together they provide strong reasons for the reliability and integrity of our products. Together they symbolize an extremely energetic program of investigation and development to provide the superior designs and precise manufacturing worthy of the leader... and you. |

|

The Product |

|

|

To meet your power requirements, GM/Electro-Motive offers Diesels in seven

configurations: 8-, 12- and 16-cylinder Roots-blown (normally aspirated),

and 8-, 12-, 16-, and 20-cylinder turbocharged models. The horsepower ranges

from 800 to 3850 hp. These leading medium-speed Diesels are designed and built to give you the greatest return on your investment - an important commitment for the energy-conscious 80's. |

|

Simplicity of design |

|

|

If you compare a GM/EMD to any other Diesel of similar size, you will notice

the GM/EMD is much simpler in design. The minimum pieces are doing the

maximum amount of work, and they are readily accessible. Our piston speeds

are slower, BMEP levels lower, and inertial stresses are lower, too. The

result is a combination of very low component wear, minimized sensitivity to

metal fatigue, and greatly extended service life. |

|

Exceptional ease of maintenance and inspection |

|

|

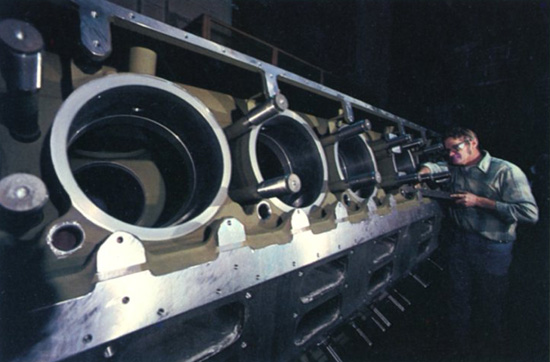

The labor hours required to change power assemblies on the 645 Diesel is

one-half to one-third that of many competitive engines. With a GM/EMD engine

there is no involvement with air intake or exhaust system connections. And

because of air inlet ports in the cylinder liner (another benefit of the

two-cycle design), a visual inspection of piston rings, pistons and liners

is quick and easy. No removal and disassembly for inspection is necessary.

Finally, because our power assemblies come as a single unit they are

interchangeable and can be retrofitted to older EMD engines. |

|

Fuel efficient |

|

|

When the price of diesel fuel rocketed from pennies a gallon to more than a

dollar a gallon, the same innovative dedication which made us number one in

our field went to work on a new challenge. The goal was simple: to make the

645 engine more efficient so that it could run on less fuel. Engineers at EMD have redesigned the turbocharger for more efficiency and redesigned the engine's piston to give the GM/EMD diesel a more efficient power stroke. They've refined the unit fuel injector to make it burn more efficiently than ever before. And they've developed a rocking piston pin that allows the engine to run at higher peak firing pressures, to name just a few innovations. These engine improvements are capable of producing savings of tens of thousands of gallons and fuel dollars per year. |

|

Smooth, fast load response |

|

|

Few Diesels on the market can match the fast response of a GM/EMD Diesel to

rapid load application. This is attributable to the two-stroke cycle design.

The benefit to you is faster response to load changes. Load response is

further enhanced by a unique turbocharger design which is directly driven

from the engine gear train through an over-running clutch until the high

engine power levels are reached. |

|

Structural Design Features |

|

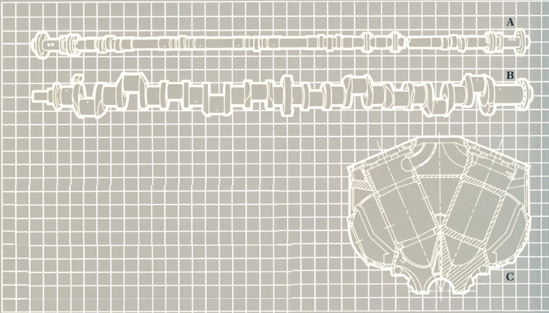

A. Camshafts are sectionalized for easy removal and installation. A. Camshafts are sectionalized for easy removal and installation.B. The forged carbon steel crankshaft provides consistent high strength. C. The crankcase is a precision weldment combining high-strength with light-weight. Highlighted here are the structural components. Access is easy via ports along both sides of the engine. * Reliable, high-performance unitized power assembly For each cylinder of the EMD Diesel, there is a power assembly consisting of a piston, liner, cylinder head and connecting rod. This assembly can be installed intact into the crankcase. With the proper tools a power assembly removal can be done in one-third the time compared to the same operation on competitive engines. * A precision-welded crankcase and oil pan In our Diesels, the engine crankcase is a precision weldment. This construction design combines lightweight and high strength with maximum component accessibility. |

|

D. The power assembly can be installed intact into the crankcase. Individual

components can also be removed as piece parts, without complete power

assembly removal. D. The power assembly can be installed intact into the crankcase. Individual

components can also be removed as piece parts, without complete power

assembly removal.* Rocking piston pin EMD's unique rocking piston pin design provides a mechanical separation between the piston pin and the pin bearing. The result is increased load carrying capacity and improved reliability. * Chrome-plated liner bore A chrome-plated liner bore and ductile iron piston ring set are available to provide extended liner life when using high-sulfur fuels. * Cylinder head and exhaust valves The cylinder head firing deck is designed to lower operating temperatures while increasing cooling and service life with no tradeoff in reliability. Inconel* exhaust valves offer unequaled resistance to thermal effects and corrosion. * High strength crankshaft and camshaft Our crankshafts are forged of carbon steel. The journals are induction-hardened. This combination provides resistance to torsional stresses, metal fatigue and wear. The camshaft is forged SAE 1080 steel, providing strength, reliability, and long life. |

|

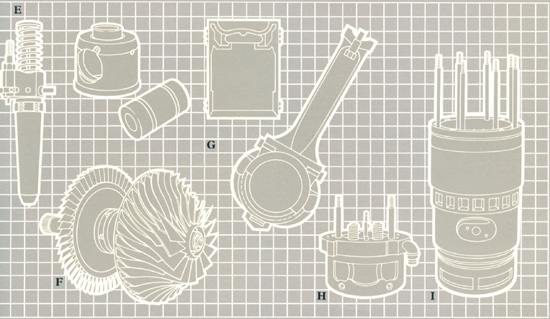

E. Unit injectors, centrally located in the cylinder head, spray into the

cylinders in a single fuel-efficient, high atomization operation. Unitized

design permits easy installation. E. Unit injectors, centrally located in the cylinder head, spray into the

cylinders in a single fuel-efficient, high atomization operation. Unitized

design permits easy installation.F. A high-efficiency turbocharger and integral impeller use exhaust gases to pack more air into cylinders. The unique design contributes significantly to optimum engine fuel usage and rapid load response. G. The 645 piston is a one-piece cast-iron symmetrical design which rotates freely, virtually eliminating piston skirt wear. A rocking piston pin bearing and carrier provide increased capacity and reliability. A trunnion type connecting rod design eliminates cylinder offset and allows a shorter crankshaft length. H. The design of the water-cooled cylinder head minimizes thermal loading influences on the cylinder head. I. The cylinder liner is of composite construction, consisting of an alloy cast iron casting with the water jacket formed by steel sleeves oven-brazed to the casting. |

|

Performance Design Features |

|

* Efficient turbocharger * Efficient turbochargerGM/EMD has kept pace in turbocharger design with the need to be fuel efficient. This has been done in concert with programs to improve reliability and component life. Performance is further enhanced by the use of high capacity gearing in the planetary gear train. * Efficient, unitized fuel injector GM/EMD was the pioneer in developing unitized fuel injection systems. That Yankee ingenuity is still alive today. In the fuel injection system, the pump and nozzle are combined with the injector in a unitized design. This eliminates troublesome, easy-to-damage, high pressure fuel lines and provides a maximum atomization of fuel, excellent combustion efficiency and low exhaust emissions. |

|

Durable Roots-blown engines |

|

|

GM/EMD Roots-blown (naturally aspirated) engines are tireless, durable

powerplants. Three-lobed helical rotors in the blower revolve in a

close-fitting aluminum housing. This design insures a generous volume of air

at low pressure. Two blowers are used on 12- and 16-cylinder engines, and

one on 8-cylinder models. |

|

The People... The Support |

|

GM's inventive genius, Charles F. Kettering, once said, "A problem is not

solved in the laboratories. It is solved in some fellow's head." In the

words of "Boss Ket" lie the key to GM/EMD's success and your assurance of a

quality product which will help you make money long into the future. For

though we have invested millions in facilities and equipment, including the

latest in space-age technology, our most important asset is our people. In

fact, an astonishing number of people who joined us more than 40 years ago

are still working at GM/EMD today. That's dedication, and it means decades

of specialized experience working for you. GM's inventive genius, Charles F. Kettering, once said, "A problem is not

solved in the laboratories. It is solved in some fellow's head." In the

words of "Boss Ket" lie the key to GM/EMD's success and your assurance of a

quality product which will help you make money long into the future. For

though we have invested millions in facilities and equipment, including the

latest in space-age technology, our most important asset is our people. In

fact, an astonishing number of people who joined us more than 40 years ago

are still working at GM/EMD today. That's dedication, and it means decades

of specialized experience working for you.Our employees: Their dedication and pride are important components of every engine we build. |

|

In the tough markets we serve, a history of experience, quality components,

fuel efficiency and good people are not enough to stay number one. You must

also provide good service and parts support. In the tough markets we serve, a history of experience, quality components,

fuel efficiency and good people are not enough to stay number one. You must

also provide good service and parts support.Unlike some engine manufacturers, we won't leave you after the sale. Each reliable GM/EMD Diesel has a service system and parts network behind it to keep downtime to an absolute minimum. And because GM/EMD Diesels are used in a variety of applications around the world, you benefit from a product support team which draws upon decades of worldwide operational experience to help you make the best possible choice of machinery that will solidly answer your needs. And with every Diesel delivered, a service engineer from this worldwide service team arrives to check it out, supervise start-up, and train customer personnel in operation, maintenance and service. Our specialists provide product support for full customer satisfaction for the life of your engine. GM/EMD also provides, free of charge, comprehensive service training at the main manufacturing plant outside Chicago. The training programs have been designed to interface with specific experiences encountered in the field. Our shipping experts know their business, too. Customer part orders are handled by experienced salespeople who are linked by sophisticated computers to our parts warehouses to provide speedy handling of any parts requirement. Designed to advanced storage standards, our new Central Parts Center at our headquarters and our strategically located outlying parts centers are capable of satisfying all parts needs. |

|

Tomorrow's GM/EMD Diesel |

|

Sixty years of leadership experience, state-of-the-art technology, the best

product, dedicated people, and a commitment to support. The Diesel engine

you buy from us today is a result of all these factors. So too, in a sense,

are the GM/EMD Diesels of tomorrow. For on the drawing boards and in the

test cells of Electro-Motive Research today are design improvements and

innovations to meet the performance, reliability and fuel efficiency

challenges of tomorrow. Sixty years of leadership experience, state-of-the-art technology, the best

product, dedicated people, and a commitment to support. The Diesel engine

you buy from us today is a result of all these factors. So too, in a sense,

are the GM/EMD Diesels of tomorrow. For on the drawing boards and in the

test cells of Electro-Motive Research today are design improvements and

innovations to meet the performance, reliability and fuel efficiency

challenges of tomorrow.The Experience, The Technology, The Product, The People, The Support. Smart business reasons for you to do business with GM/EMD. ELECTRO-MOTIVE |

|

|

Gå:

tilbage

- op Opdateret fredag, 03 januar 2025 06:57:02 |

|